Reinforced braid hoses master pressure containment. They handle extreme internal forces safely. These specialized hoses maintain system integrity under stress. Their unique construction prevents failures during operation. Engineers worldwide specify them for high-pressure applications. The reinforcement provides exceptional burst resistance. This guide explores their pressure capabilities in detail. We explain construction techniques and performance benefits. You will learn about their diverse industrial applications. We answer crucial technical questions too. Understanding pressure ratings ensures operational safety. Proper selection prevents costly system downtime.

Frequently Asked Questions (FAQ)

1. How does reinforcement improve pressure rating?

The braid adds tensile strength. It contains internal pressure effectively. This prevents tube expansion. Burst resistance increases significantly.

2. What factors affect pressure capacity?

Braid material quality matters. Number of layers changes rating. Wire thickness influences strength. Crimp quality affects performance.

3. How to read pressure ratings?

Working pressure is key. Burst pressure is much higher. Always include safety factors. Consider pressure spike potential.

4. Does temperature affect pressure capacity?

Yes, heat reduces strength. Cold makes materials brittle. Check temperature ratings carefully. Derate for extreme conditions.

5. How often should pressure tests occur?

Follow manufacturer guidelines. Test during installation first. Regular inspections are crucial. Monitor for pressure drops.

Basic Definition and Key Characteristics

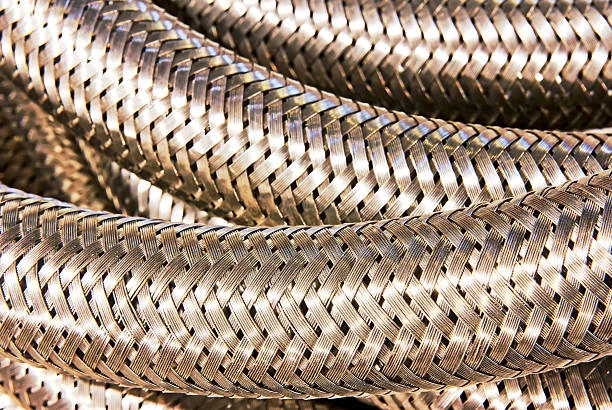

Reinforced braid hoses contain pressure. They feature layered construction. An inner tube carries fluid. Reinforcement layers surround it.

Braid reinforcement is common. Stainless steel wires cross weave. This creates flexible strength. Pressure resistance improves greatly.

These hoses offer great advantages. They handle high system pressures. Flexibility remains excellent. Installation becomes easier.

Pressure performance is outstanding. They withstand constant high pressure. Pressure spikes cause no damage. System safety improves.

Flexibility under pressure is key. They bend without kinking. Connections stay secure. Vibration damping occurs.

Durability is very impressive. They resist abrasion well. External damage reduces. Service life extends.

Temperature tolerance helps performance. They work in heat. Cold conditions pose no problem. Materials stay stable.

Common Uses and Application Industries

These hoses serve high-pressure systems. Their reliability is proven everywhere.

Hydraulic systems use them extensively. Construction equipment depends on them. Excavators need high-pressure lines. Cranes use them for lifting.

Industrial automation requires them. Robots use hydraulic power. Assembly lines need reliable flow. Pressure must remain constant.

Oil and gas industry needs them. Drilling equipment uses extreme pressure. Well control systems rely on them. Safety is absolutely critical.

Manufacturing plants use them widely. Injection molding requires high pressure. Metal forming needs force transfer. These hoses deliver power.

Energy sector applications exist. Power generation uses high pressure. Turbine systems need reliable hoses. Pressure control is vital.

Aerospace industry uses them. Aircraft hydraulic systems need them. Landing gear operates under pressure. Flight controls depend on them.

Automotive testing uses them. Brake system tests need pressure. Fuel injection systems require them. Performance must be accurate.

Summary

Reinforced braid hoses handle pressure. They enable modern high-force systems. Their construction is engineered precisely. The reinforcement contains energy safely.

Many industries benefit greatly. Operational safety improves significantly. System performance increases reliably. Maintenance costs reduce over time.

Choosing the right hose matters. Pressure ratings are crucial parameters. Proper installation ensures safety. Regular maintenance prevents failures.

These hoses solve pressure challenges. They move fluids under extreme force. Engineers trust their capabilities completely. They are vital components everywhere.

IFNS’s international standards

IFNS products comply with a wide range of international standards, including ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, GB/T 18993 series, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications ensure that our pipes and fittings meet global quality, safety, and performance requirements.

Connect

IFNS, a Chinese manufacturer with 30 years of experience, specializes in high-quality plastic pipes, fittings, and valves. Interested in IFNS’s copper fittings, copper valves, plastic pipes, or fittings? Contact us today. IFNS offers a wide range of standard pipes tailored to your needs. Explore our affordable, cost-effective valve and piping system products.

We respond to emails or faxes within 24 hours. For immediate assistance, call us anytime with questions about our products.