Imagine discovering a small, persistent leak in your laundry room that has slowly damaged flooring and cabinetry. The culprit? A degraded reinforced braid hose that failed due to neglect. These vital components serve as the flexible arteries of your home’s plumbing and hydraulic systems, quietly delivering water and other media where needed. While renowned for their durability, reinforced braid hoses still require proper care to ensure their longevity and safe operation. This comprehensive guide explores the essential practices for maintaining your reinforced braid hoses. We will answer common questions, review their fundamental characteristics, and examine their widespread applications. Understanding proper maintenance will help you prevent failures, extend service life, and protect your property from costly damage.

Basic Definition and Key Characteristics

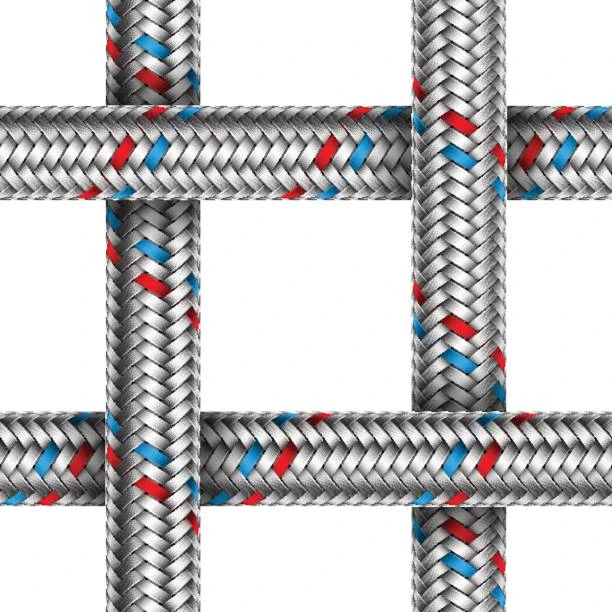

Reinforced braid hoses are flexible conduits designed for conveying fluids under pressure. They feature a sophisticated multi-layer construction that gives them both strength and flexibility. The inner tube is compatible with the specific fluid being transported, whether water, oil, or chemicals. A reinforcement layer, typically made of braided stainless steel or synthetic fibers, surrounds this inner tube. This braid provides tremendous tensile strength and contains the internal pressure. A durable outer cover protects the reinforcement from abrasion, chemicals, and environmental damage.

These hoses possess several important characteristics that influence their maintenance needs. Their flexibility allows them to withstand vibration and movement, but this same flexibility makes them susceptible to wear at connection points. The materials resist corrosion, but they can still degrade from prolonged exposure to harsh environments. Their braided construction provides excellent burst strength, but the wires can fatigue from constant pressure cycles. Understanding these characteristics is essential for developing an effective maintenance program that addresses their unique strengths and vulnerabilities.

Frequently Asked Questions (FAQ)

1. How often should I inspect my reinforced braid hoses?

You should perform visual inspections at least every three months. For high-pressure applications or systems experiencing vibration, monthly inspections are better. Always check hoses before putting equipment into service after storage. Create a regular schedule based on your specific usage patterns and environmental conditions.

2. What specific signs of wear should I look for during inspections?

Look for several key indicators of potential problems. Check for abrasions on the outer cover that might expose the reinforcement braid. Watch for cracks in the hose cover, especially near fittings. Notice any swelling or softening of the hose material. Look for leaks at connection points or along the hose length. Identify any kinks or twists that might restrict flow.

3. Can I repair a damaged reinforced braid hose myself?

No, you should never attempt to repair a damaged hose. Reinforced braid hoses operate under pressure, and DIY repairs can create dangerous failure points. Always replace damaged hoses with appropriate replacements rated for your specific application. Professional installation ensures proper fitting attachment and system integrity.

4. How does temperature affect hose lifespan and maintenance?

Temperature significantly impacts hose performance and durability. High temperatures can accelerate the aging process of the inner tube and outer cover. Extreme cold can make some materials brittle and prone to cracking. Always ensure your hoses are rated for the temperature ranges they will experience. Provide additional protection for hoses in extreme temperature environments.

5. What is the typical lifespan of a reinforced braid hose?

The service life varies considerably based on application and conditions. High-pressure hydraulic hoses might need replacement every 1-2 years with heavy use. Residential water supply hoses often last 5-8 years. Always follow manufacturer recommendations and replace hoses that show signs of wear regardless of age. Document installation dates to track hose age accurately.

Common Uses and Application Industries

Reinforced braid hoses serve critical functions across numerous industries, each with unique maintenance requirements. In residential applications, they connect water supply lines to fixtures like toilets, sinks, and washing machines. Homeowners must regularly check these hoses for signs of wear, as failures can cause significant water damage. The automotive industry uses these hoses for power steering, brake systems, and turbocharger connections. Mechanics incorporate hose inspection into routine maintenance schedules to ensure vehicle safety.

Industrial manufacturing facilities rely on reinforced hoses for hydraulic systems, pneumatic tools, and material transfer. These environments require rigorous maintenance programs due to the constant operation and safety implications of hose failures. The construction industry uses these hoses in heavy equipment like excavators and bulldozers, where regular inspection prevents downtime and accidents on job sites. Agricultural applications include irrigation systems and tractor hydraulics, where hoses face sun exposure and chemical contact that accelerate degradation.

Even the aerospace industry utilizes specialized reinforced hoses for fuel and hydraulic systems, with extremely strict maintenance protocols and replacement schedules. Across all these applications, proper maintenance practices share common elements: regular inspection, appropriate installation, environmental protection, and timely replacement. Understanding how these hoses function in different contexts helps develop effective, application-specific maintenance strategies.

Conclusion

In conclusion, maintaining your reinforced braid hoses is not just about preventing failures—it’s about ensuring safety, reliability, and cost-effectiveness throughout your systems. These components may seem simple, but their proper functioning is often critical to larger operations. Regular inspection, appropriate installation, and timely replacement form the foundation of good hose maintenance. Understanding the specific requirements of your application helps you develop an effective maintenance schedule.

Remember that prevention always costs less than repair, especially when considering potential damage from failures. Document your maintenance activities and keep records of installation dates. Always use hoses rated for your specific pressure, temperature, and media requirements. When in doubt, consult with professionals who can assess your specific situation. By implementing these maintenance practices, you ensure that your reinforced braid hoses perform reliably throughout their service life, protecting your equipment and providing peace of mind.

IFNS’s international standards

IFNS products comply with a wide range of international standards, including ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, GB/T 18993 series, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications ensure that our pipes and fittings meet global quality, safety, and performance requirements.

Connect

IFNS, a Chinese manufacturer with 30 years of experience, specializes in high-quality plastic pipes, fittings, and valves. Interested in IFNS’s copper fittings, copper valves, plastic pipes, or fittings? Contact us today. IFNS offers a wide range of standard pipes tailored to your needs. Explore our affordable, cost-effective valve and piping system products.

We respond to emails or faxes within 24 hours. For immediate assistance, call us anytime with questions about our products.