Reinforced braid hoses are essential components in many industries, offering durability, flexibility, and resistance to high pressure and extreme temperatures. These hoses feature a strong inner tube, reinforced with braided metal or synthetic fibers, ensuring long-lasting performance in demanding environments. Whether used in automotive, industrial, or hydraulic systems, they play a crucial role in fluid and gas transfer. This guide covers their definition, key features, common applications, maintenance tips, and answers to frequently asked questions.

What Are Reinforced Braid Hoses? Key Features

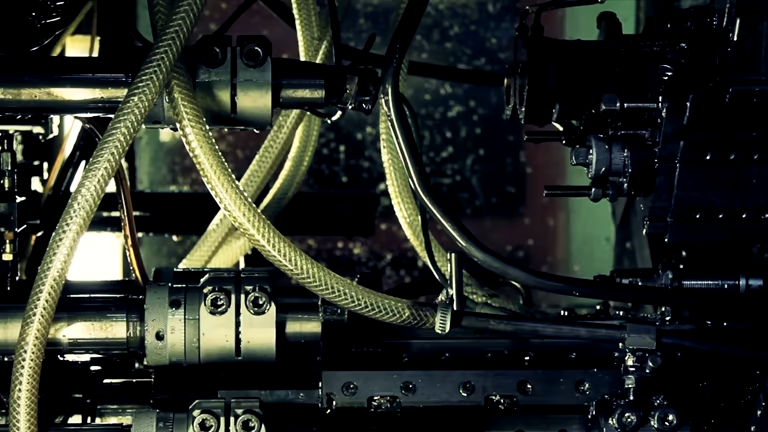

Reinforced braid hoses consist of multiple layers designed for strength and flexibility. The core structure includes:

- Inner Tube: Made from rubber, PTFE, or thermoplastic, ensuring chemical resistance and smooth fluid flow.

- Reinforcement Layer: Braided metal (stainless steel, carbon steel) or synthetic fibers (aramid, polyester) for added pressure resistance.

- Outer Cover: Protects against abrasion, weather, and external damage.

Key Advantages:

✔ High pressure and temperature resistance

✔ Excellent flexibility for tight installations

✔ Long service life with minimal maintenance

✔ Resistant to corrosion, chemicals, and wear

Common Uses & Industries

Reinforced braid hoses serve critical roles in various sectors:

1. Automotive & Transportation

- Fuel lines: Handle gasoline, diesel, and biofuels without degradation.

- Brake systems: Withstand high hydraulic pressure for reliable braking.

- Coolant & oil transfer: Maintain efficiency in engine cooling and lubrication.

2. Industrial & Manufacturing

- Hydraulic systems: Power heavy machinery with high-pressure fluid transfer.

- Pneumatic tools: Supply compressed air without leaks or bursts.

- Chemical processing: Safely transport acids, solvents, and aggressive fluids.

3. Oil & Gas

- Drilling operations: Resist extreme pressures and abrasive materials.

- Refineries: Transport petroleum products safely under high heat.

4. Agriculture & Construction

- Irrigation systems: Durable against weather and mechanical stress.

- Heavy equipment: Reliable fluid transfer in excavators and loaders.

Frequently Asked Questions (FAQ)

1. How long do reinforced braid hoses last?

With proper maintenance, they typically last 5-10 years, depending on usage conditions. Exposure to extreme heat, chemicals, or constant bending may shorten lifespan.

2. Can I repair a damaged braided hose?

Minor leaks can sometimes be fixed with hose repair sleeves, but severely damaged hoses should be replaced for safety.

3. What’s the difference between metal and synthetic braiding?

Metal braiding offers higher pressure resistance, while synthetic fibers (like aramid) provide flexibility and corrosion resistance.

4. How do I choose the right hose for my application?

Consider factors like pressure rating, temperature range, fluid type, and environmental conditions. Always check manufacturer specifications.

5. Why does my braided hose keep leaking?

Common causes include improper installation, wear from friction, chemical degradation, or exceeding pressure limits. Regular inspections help prevent leaks.

Maintenance Tips for Longevity

To maximize the lifespan of reinforced braid hoses:

✅ Inspect regularly for cracks, bulges, or leaks.

✅ Avoid sharp bends that strain the reinforcement.

✅ Clean after exposure to corrosive chemicals.

✅ Replace at first signs of significant wear.

✅ Follow pressure ratings to prevent bursts.

Conclusion

Reinforced braid hoses are vital for industries requiring durable, high-performance fluid transfer solutions. Their multi-layer construction ensures reliability under pressure, heat, and harsh conditions. By understanding their features, applications, and maintenance needs, users can optimize performance and prevent failures. Whether in automotive, industrial, or hydraulic systems, choosing the right hose and caring for it properly ensures efficiency and safety.

Would you like any refinements or additional details on specific aspects?

IFNS’s international standards

IFNS products comply with a wide range of international standards, including ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, GB/T 18993 series, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications ensure that our pipes and fittings meet global quality, safety, and performance requirements.

Connect

IFNS, a Chinese manufacturer with 30 years of experience, specializes in high-quality plastic pipes, fittings, and valves. Interested in IFNS’s copper fittings, copper valves, plastic pipes, or fittings? Contact us today. IFNS offers a wide range of standard pipes tailored to your needs. Explore our affordable, cost-effective valve and piping system products.

We respond to emails or faxes within 24 hours. For immediate assistance, call us anytime with questions about our products.