Common Mistakes in Faucet Repairs

Fixing a leaky or malfunctioning faucet seems simple, but even small errors can lead to major plumbing issues down the line. Whether you’re repairing a hose tap in the garden or a mixer faucet in the kitchen, it’s easy to overlook important steps or make assumptions that compromise the repair. This article highlights the most common faucet repair mistakes, explains how to avoid them, and guides you through selecting the right components such as brass valves. You’ll also learn about proper installation, usage across different industries, and how brass valves compare to plastic alternatives.

Frequently Asked Questions (FAQ)

1. Why does my hose tap keep leaking even after replacing the washer?

A leaking hose tap after washer replacement usually means the valve seat is worn or the washer isn’t properly sized. It could also be due to overtightening, which damages internal components.

2. How do I know if I should repair or replace a faucet?

If the faucet is old, corroded, or repeatedly leaking despite repairs, replacement is more cost-effective. But for minor issues like a loose handle or worn washer, a simple repair is sufficient.

3. Can I use a kitchen faucet cartridge in a hose tap?

No. Faucets and hose taps use different mechanisms and pressure tolerances. Always use components designed specifically for the tap’s function and environment.

4. Is plumber’s tape necessary during faucet repair?

Yes. PTFE (plumber’s) tape helps seal threaded connections, especially in hose taps and external plumbing. It prevents leaks and provides a secure fit.

5. What tools do I need for faucet repair?

Basic tools include a wrench, screwdriver, pliers, replacement washers or cartridges, plumber’s tape, and a cloth. For outdoor hose taps, you may also need a valve key or hose spanner.

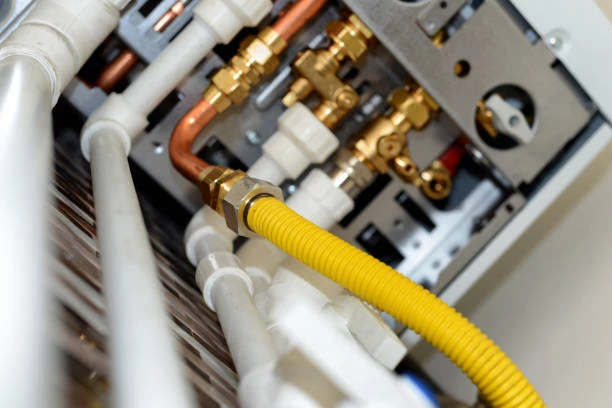

Brass Valve Basics: Definition and Features

A brass valve is a plumbing component used to regulate water flow. Made from an alloy of copper and zinc, brass valves are known for their durability, corrosion resistance, and strength. They are widely used in both indoor and outdoor plumbing systems, including hose taps, due to their reliable sealing and high temperature tolerance.

Key Features of Brass Valves:

Durability: Can withstand long-term water exposure and mechanical wear.

Corrosion Resistance: Resists rust and mineral buildup better than steel or iron.

Thermal Stability: Suitable for both cold and hot water systems.

Precision Engineering: Ensures tight sealing and smooth operation.

Lead-Free Options: Available for potable water applications.

Brass valves are ideal for repairing or installing hose taps, especially in environments exposed to weather or pressure changes.

Common Applications and Industry Use

Brass valves and hose taps are versatile, supporting a wide range of uses across industries. Their durability and reliability make them a favorite for professionals and homeowners alike.

Residential:

Garden hose taps for irrigation

Outdoor faucets for car washing

Basement utility sinks

Commercial:

Restaurant kitchens for utility sinks and cleaning stations

Laundry services for high-use water access points

Industrial:

Factory cooling systems

Chemical processing pipelines using brass ball valves

Water treatment plants with frequent hose tap access

Agricultural:

Field irrigation systems

Greenhouse hose taps for spray or drip irrigation

Whether in homes, farms, or factories, maintaining hose taps and valves prevents water waste and ensures consistent performance.

Buying Guide: Choosing the Right Valve and Tap

Choosing the right components, especially for hose taps, ensures performance, safety, and durability. Here’s what to check when shopping:

1. Material

Brass: Best for longevity, outdoor use, and high-pressure areas.

Plastic: Affordable and corrosion-proof, but not suitable for high temperatures or pressure.

2. Certifications

Look for international product standards, such as:

ISO

NSF/ANSI for potable water

EN or DIN for European compliance

These certifications guarantee safety and performance.

3. Finish

Polished chrome for indoor style

Coated brass or matte finishes for outdoor durability

4. Compatibility

Ensure the valve matches the existing hose or plumbing thread size (½”, ¾”, etc.) and check pressure ratings for specific uses.

5. Seal Type

Look for rubber or silicone washers and ceramic cartridges for long-lasting leak protection. For outdoor hose taps, a brass spindle with rubber seals is ideal.

Installation Tips: Avoiding Mistakes from the Start

Even the best tap or valve won’t work well if installed incorrectly. Here are important steps and tips for proper installation:

Pre-Installation:

Shut off the water supply before beginning any work.

Clean the thread areas and remove any mineral buildup.

Check that the parts and tools are ready.

During Installation:

Use PTFE Tape: Wrap around the threads to prevent leaks.

Tighten Gently: Avoid overtightening, which can crack plastic or warp brass threads.

Align Properly: Make sure the tap aligns straight with the outlet or hose.

Test Slowly: After installing, open the valve slowly to check for leaks and pressure issues.

Post-Installation:

Test sealing with water at full pressure.

Recheck for drips or unusual sounds.

Make adjustments if necessary.

Regular checks every few months will help keep the system in top condition.

Brass vs. Plastic Valves: A Side-by-Side Comparison

When repairing or replacing a hose tap, you’ll often need to choose between brass and plastic valves. Here’s a quick comparison to help make the decision:

| Feature | Brass Valve | Plastic Valve |

|---|---|---|

| Durability | Excellent (15–20 years) | Moderate (5–10 years) |

| Pressure Resistance | High | Moderate |

| Temperature Tolerance | Excellent (hot & cold water) | Lower (not ideal for hot water) |

| Corrosion Resistance | High | Very High |

| Weight | Heavy | Lightweight |

| Cost | More expensive | More affordable |

| Use Case | Ideal for hose taps, kitchens, industry | Good for temporary or low-use settings |

| Recyclability | Fully recyclable | Depends on plastic type |

For long-term performance in hose tap applications—especially outdoors—brass valves are usually the better choice.

Conclusion

Faucet repair may seem straightforward, but small mistakes—like using the wrong washer, skipping seal tape, or misaligning components—can lead to persistent leaks or system damage. Understanding your valve materials, especially the advantages of brass for hose taps, goes a long way in ensuring reliable water flow and proper sealing. Whether you’re fixing a tap in your backyard or replacing valves in a large building, knowing what to avoid and what to look for can save you time, water, and money.

Connect

IFNS is a trusted Chinese manufacturer with 30 years of experience in producing plastic pipes, fittings, and valves. We offer a wide range of products including copper fittings, brass valves, and solutions for both hot and cold water systems—perfect for residential, commercial, and industrial use.

If you’re interested in long-lasting hose tap valves or other plumbing solutions, contact us for professional advice and high-quality products that meet international standards.

Contact Information:

We respond to all emails or faxes within 24 hours. For urgent inquiries or detailed product questions, you can call us anytime.

IFNS Products and International Standards

All IFNS products meet a broad range of international certifications and standards, including:

ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), ASTM D2241, D2729, F441/F441M series, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and more.

By choosing IFNS, you ensure your plumbing systems are supported by dependable, certified, and cost-effective solutions.