Future PPR Piping Materials

Polypropylene Random Copolymer (PPR) pipes have become essential in modern plumbing and heating systems. Their environmental adaptability ensures durability and safety in diverse conditions. This article explores PPR pipe heater features, uses, and future developments, guiding buyers and installers to make informed decisions.

Frequently Asked Questions (FAQ)

Q1: What is a PPR pipe heater?

A PPR pipe heater warms PPR pipes to prevent freezing and maintain water temperature.

Q2: Why choose PPR pipes over other materials?

PPR pipes resist corrosion, handle high temperatures, and last longer than many alternatives.

Q3: Are PPR pipes suitable for outdoor use?

Yes, modern PPR pipes withstand UV exposure and extreme weather conditions with proper installation.

Q4: How do I select quality PPR pipes?

Check material composition, color consistency, and certifications such as ISO and ASTM standards.

Q5: Can I install PPR pipes myself?

Professional installation is recommended to ensure correct heating and secure connections.

What is PPR? Basic Definition and Characteristics

PPR stands for Polypropylene Random Copolymer, a thermoplastic polymer used to manufacture piping systems. It offers excellent chemical resistance, high-temperature tolerance up to 95°C, and superior mechanical strength. The material remains stable under pressure and resists scaling and corrosion. Additionally, PPR pipes provide a non-toxic solution for potable water and heating systems. Their smooth interior reduces friction, enhancing flow efficiency.

Common Uses and Application Industries

PPR pipes serve various sectors due to their versatility:

- Residential plumbing: Ideal for hot and cold water supply because of safety and durability.

- Heating systems: PPR pipe heaters help maintain consistent temperatures in underfloor heating setups.

- Industrial fluid transport: Resistant to many chemicals, suitable for non-corrosive industrial liquids.

- Agriculture: Used in irrigation systems for their resistance to environmental stress.

- Medical and laboratory: High hygiene standards make them fit for clean water and chemical delivery.

Buying Guide: What to Look For

Material Quality:

Choose pipes made from 100% virgin PPR resin. Avoid recycled materials to ensure longevity.

Color Coding:

Common colors include green, white, and gray. Color helps identify pipe type but does not guarantee quality.

Certifications:

Look for ISO 15874, ASTM F2389, DIN 8077/8078, or equivalent certifications to ensure compliance with international standards.

Brand Reputation:

Select trusted brands with proven manufacturing processes and positive customer feedback.

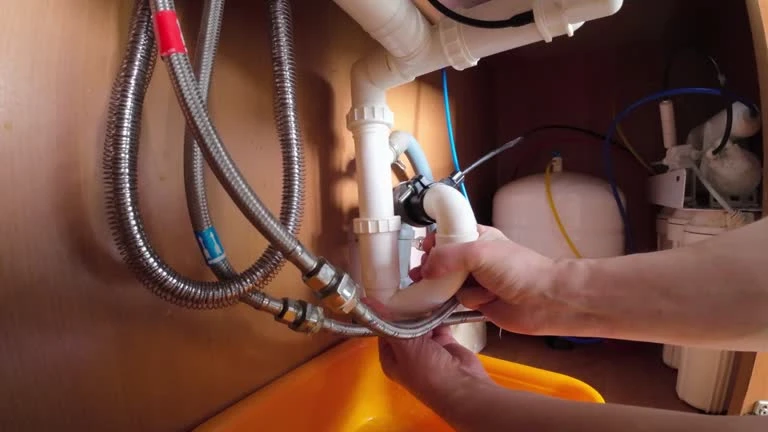

Installation Tips for PPR Pipes and Heaters

Use specialized welding equipment for heat fusion connections, maintaining temperatures around 260°C. Ensure pipe ends remain stationary for at least 30 seconds after welding to solidify joints. Avoid installation in freezing conditions to prevent brittleness. When installing PPR pipe heaters, follow manufacturer guidelines closely for electrical safety and optimal performance. Always embed pipes with protective sleeves when routing through walls to accommodate thermal expansion.

PPR vs Other Piping Materials: A Comparative Overview

| Feature | PPR Pipe | PVC Pipe | Copper Pipe |

|---|---|---|---|

| Temperature Tolerance | Up to 95°C | Up to 60°C | Up to 120°C |

| Corrosion Resistance | Excellent | Moderate | Good |

| Flexibility | Moderate | Low | Low |

| Installation Method | Heat fusion welding | Solvent cement | Soldering or compression |

| Suitable for Hot Water | Yes | No | Yes |

| Lifespan | 50+ years | 20-30 years | 40+ years |

Conclusion

Future PPR piping materials will focus increasingly on environmental adaptability, enhancing resistance to temperature fluctuations and UV exposure. Their durability, safety, and eco-friendliness make them a top choice for heating and plumbing applications. Choosing certified, high-quality PPR pipes and heaters ensures long-term efficiency and peace of mind.

Contact IFNS

Looking for certified, stylish, and durable sanitary ware? Contact IFNS for premium PPR pipe heaters and piping solutions. Our experts provide OEM services, free samples, and technical support tailored to your needs.

For more information,pls visit our webside https://ifns.su/

Whatsapp: +86 15088288323

IFNS Products International Standards

IFNS products comply with a wide range of international standards, including ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, and many others. These certifications guarantee product quality, safety, and reliability across global markets.