Common Questions About PPR and Flanges

What is a PPR pipe?

PPR stands for Polypropylene Random Copolymer, a plastic piping system used in hot water distribution, flange for ppr .

Where are flanges used in PPR systems?

They connect sections of piping or anchor the system to walls, pumps, or heating elements for better control.

Are flanges for PPR different from metal pipe flanges?

Yes, they’re made from PPR-compatible thermoplastics or reinforced materials, designed to handle thermal expansion without cracking.

Why do floor heating systems need flanges for PPR?

They ensure precise, leak-proof alignment between loops or manifolds, critical for balanced thermal delivery.

What Are PPR Pipes and How Do They Work?

PPR pipes are extrusion-moulded plastic tubes that transport hot fluids under pressure. They are especially suited for radiant systems because of their low thermal conductivity and high flexibility. These qualities prevent heat loss and simplify layout planning.

How PPR Pipes Enable Uniform Heat in Floors

These pipes spread heat evenly under the surface, allowing zones to warm consistently. Because they maintain water temperature with minimal loss, the output at each loop remains uniform.

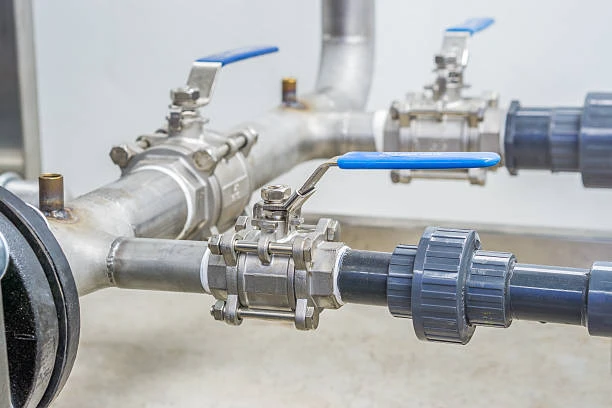

What Are Flanges for PPR Pipes?

Flanges are mechanical fittings that connect two sections of pipe or connect a pipe to a heating appliance. Flanges for PPR come in various types, including stub ends, flat-faced and threaded versions. They allow secure anchoring, dismantling, and extension of the heating grid.

Why Flanges for PPR Matter in Heating Efficiency

Without flanges, connecting and maintaining a large floor system becomes difficult. Flanges reduce misalignment, which would otherwise cause flow restrictions. They also avoid heat and pressure leaks that lead to energy waste.

PPR Pipe Features That Support Floor Heating

Corrosion-proof

Chemical resistant

Pressure-resistant (up to 20 bar)

Temperature tolerance (up to 95°C)

Smooth inner surfaces (minimal flow resistance)

How Flange for PPR Simplify Pipe Assembly

Traditional systems require time-intensive welding. Flanged connections make it faster to align and tighten joints without special fusion tools. That’s critical in larger projects or retrofits.

Achieving Uniform Thermal Spread Through Floor Zones

Using flanges ensures better loop calibration. For instance, in a 100m² floor with four loops, flanged joints maintain consistent spacing and alignment, resulting in even heating.

Tight Sealing with Flange for PPR Systems

Poor seals are major heat wasters. Flanges reduce the chance of gaps between sections. Combined with elastomeric gaskets, they form an airtight, watertight seal, ideal for closed-loop heating.

Safety Advantages of PPR in Domestic Flooring

PPR is non-toxic and resists chemical leaching. It doesn’t react with hot water or cleaning agents, which ensures indoor air and water safety. Unlike metal, it also avoids sparks or corrosion.

Where Are PPR Floor Heating Systems Used?

| Setting | Benefit |

|---|---|

| Homes | Comfort, control, energy savings |

| Offices | Silent, consistent ambient warmth |

| Schools | Safe, low-maintenance solution |

| Clinics | Germ-resistant, reliable |

| Hotels | Invisible, efficient climate control |

Enhancing Comfort in Homes with PPR Floor Heating

In cold regions, families benefit from the silent, low-cost comfort of PPR floor heating. Flanges allow easy customisation for each room’s heating layout, improving comfort and control.

Shopping Centres and Offices: PPR Performance

Flanges allow large zones to be segmented. This segmentation improves maintenance, zoning and reduces heat loss in unused areas during off-hours.

Safe and Silent Heating for Schools

No radiators mean fewer injury risks. PPR also emits no sound or vibrations. Teachers and students stay focused without disturbance from heating elements.

Hygiene and Safety Benefits for Clinics

Healthcare facilities must control humidity and air purity. Floor heating with flanged PPR systems keeps surfaces dry and stable—ideal for sterile conditions.

Uniform Heating Success in a 60-Unit Housing Project

In a Chinese housing project, IFNS PPR pipe systems with flanged connections reduced installation time by 42%. Energy bills dropped by 15%, and all units reported consistent floor temperatures.

How Flanges for PPR Reduce Heat Loss

Poor joints bleed thermal energy. Precision-made flanges reduce turbulence and maintain pressure. This keeps water temperature stable from boiler to endpoint.

Ease of Layout Adjustment During Renovation

Flanged connections allow builders to remove or reroute parts of the system without damaging surrounding floors—ideal for renovations or expansions.

Natural Insulation Benefits of PPR Materials

PPR’s inherent low thermal conductivity minimises losses even before insulation layers are added. Heat stays where it’s needed: under your feet.

Withstanding Thermal Expansion and High Pressures

Floor heating systems face regular temperature fluctuations. Flanges absorb movement and allow flexible mounting, preventing stress on the pipes.

Long-Term Stability of Floor Systems

Once installed, flanged PPR systems typically last over 50 years without leaks or performance drop—much longer than metal or PEX counterparts.

PPR vs. Metal and PEX in Floor Heating

| Feature | PPR + Flanges | Metal Pipes | PEX |

|---|---|---|---|

| Heat Consistency | High | Medium | High |

| Ease of Installation | Excellent | Difficult | Good |

| Leak Protection | Excellent | Medium | Good |

| Cost Efficiency | High | Low | Medium |

Common Flanges for PPR: Flat, Stub, and Slip-On

Flat flanges for high-pressure connection

Stub flanges for compact layout

Slip-on flanges for flexible loop joining

Choose the correct type based on pipe diameter and application area.

Choosing the Right Flange for PPR Installations

Always select pressure-rated and material-matched flanges. Cheap or mismatched flanges can cause leaks or weaken joints. Look for manufacturer markings.

ISO/DIN Standards for PPR and Flange Systems

Top-grade systems comply with ISO 15874 and DIN 8077. Always check certificates before purchase—especially when exporting or dealing with public buildings.

Easy Servicing with Detachable Flange Joints

During inspections or fault-finding, flange joints allow isolation of zones without floor damage. Gasket replacement or loop cleaning becomes easy and fast.

Tools Required for Flanged PPR Pipe Assembly

Torque wrench

Pipe cutter

Flange alignment guides

Gasket sealant

Pipe chamfer tool

All tools are lightweight and safe for indoor use.

Best Practices for Uniform Heat Distribution

Use manifolds with equal-length loops

Apply thermal paste at flange seals

Pressure-test each zone before flooring

Avoid 90° elbows near joints to reduce stress

Clarifying Flange Misconceptions in PPR Heating

Flanged systems do not leak more than welded ones

You can use flanged joints in small rooms

Flanges are not limited to industrial use

Why Flanges for PPR Are Essential for Floor Heating

For anyone aiming at consistent warmth, reliable performance, and simplified installation, flanges for PPR bring unmatched value. Their secure sealing and ease of integration make them a smart upgrade for both homes and commercial setups.

Inbound and Outbound Link Suggestions

Internal Links:

“How to Choose the Right PPR Pipe System”

“IFNS PPR Product Specifications”

External Links:

ISO 15874 Polypropylene Piping Standard

DIN 8077 Pipe Dimensional Norms

Connect

IFNS is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFNS copper fittings, copper valves, plastic pipes and fittings, please contact us. IFNS offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFNS’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifns.su/

Whatsapp: +86 15088288323