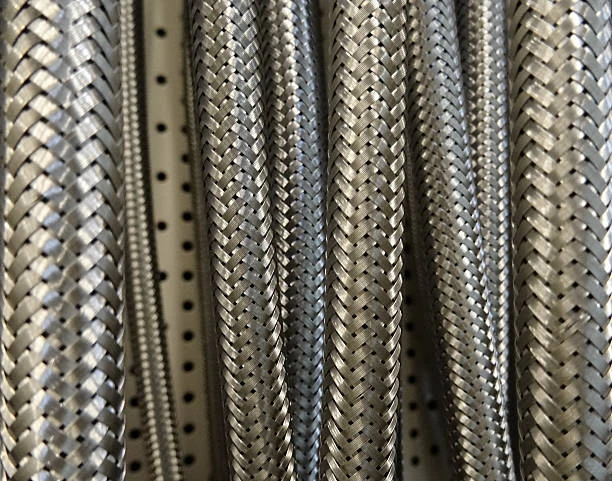

Reinforced braid hoses require proper operation. They need correct handling techniques. These hoses perform best with good practices. Their construction demands specific operational care. Engineers follow strict procedures with them. Operational knowledge prevents most failures. This guide explains proper operating methods. We cover installation and maintenance steps. You will learn usage best practices. We answer common operational questions. Understanding operation ensures safety. Proper use extends service life.

Frequently Asked Questions (FAQ)

1. How to install these hoses properly?

Measure length requirements first. Avoid twisting during installation. Maintain minimum bend radius. Use correct fitting procedures.

2. What pressure precautions are necessary?

Never exceed rated pressure. Monitor for pressure spikes. Install pressure relief devices. Check for leaks regularly.

3. How to handle temperature extremes?

Allow gradual temperature changes. Avoid rapid heating or cooling. Monitor temperature gauges closely. Use insulation when needed.

4. What maintenance is required?

Conduct visual inspections often. Check for abrasion signs. Test fitting security regularly. Replace at first damage signs.

5. How to store these hoses correctly?

Coil them loosely for storage. Avoid kinks or sharp bends. Keep in clean, dry areas. Protect from sunlight exposure.

Basic Definition and Key Characteristics

Reinforced braid hoses need careful operation. They have specific handling requirements. The inner tube carries media. Reinforcement provides strength. Outer cover offers protection.

Operational factors are crucial. Pressure must stay within limits. Temperature ranges require respect. Flow rates need monitoring.

These hoses offer operational advantages.

Pressure management is key. Operators must watch gauges. Sudden spikes can cause damage. Steady pressure ensures safety.

Temperature control matters greatly. Heat requires monitoring. Cold needs attention too. Operators record temperatures.

Flow rate monitoring helps. Turbulence indicates problems. Smooth flow means good operation. Operators adjust valves.

Movement handling is important. Flexing must be controlled. Bending should stay within limits. Twisting must be avoided.

Common Uses and Application Industries

These hoses serve many operations. Their handling varies by industry.

Hydraulic systems use them daily. Operators control pressure carefully. They monitor flow constantly. They check temperatures regularly.

Industrial automation needs them. Robots move hoses constantly. Operators ensure smooth motion. They prevent sharp bending.

Construction equipment operates them. Operators avoid rough handling. They protect from abrasion. They check connections often.

Manufacturing plants use them. Production lines move hoses. Operators route them properly. They secure them correctly.

Marine applications involve them. Crews handle saltwater exposure. They rinse hoses after use. They inspect for corrosion.

Chemical processing requires care. Operators wear protective gear. They check chemical compatibility. They monitor for leaks.

Energy sector uses them. Plant operators follow procedures. They maintain pressure logs. They record temperature data.

Summary

Reinforced braid hoses need proper operation. Handling techniques affect performance. Installation requires care and attention. Maintenance ensures long service life.

Many industries use these hoses. Operational knowledge prevents accidents. System reliability improves greatly. Downtime reduces significantly.

Following procedures matters greatly. Pressure limits must be respected. Temperature ranges should be monitored. Movement should be controlled.

These hoses perform well when operated correctly. They deliver reliable service. Operators trust their capabilities. Good practices ensure success.

IFNS’s international standards

IFNS products comply with a wide range of international standards, including ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, GB/T 18993 series, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications ensure that our pipes and fittings meet global quality, safety, and performance requirements.

Connect

IFNS, a Chinese manufacturer with 30 years of experience, specializes in high-quality plastic pipes, fittings, and valves. Interested in IFNS’s copper fittings, copper valves, plastic pipes, or fittings? Contact us today. IFNS offers a wide range of standard pipes tailored to your needs. Explore our affordable, cost-effective valve and piping system products.

We respond to emails or faxes within 24 hours. For immediate assistance, call us anytime with questions about our products.