Imagine a high-pressure hydraulic system failing on a construction site or a critical coolant line bursting in an industrial machine. These scenarios often result from one component failing: the hose. Reinforced braid hoses are the unsung heroes that prevent such catastrophes. These are not simple tubes; they are engineering marvels designed to withstand extreme pressure, temperature, and abrasive conditions. This comprehensive guide explores the immense importance of reinforced braid hoses. We will define their construction, answer vital questions, and examine their diverse applications. Understanding their critical role will help you appreciate why selecting the right hose is paramount for safety, efficiency, and reliability in countless systems.

Basic Definition and Key Characteristics

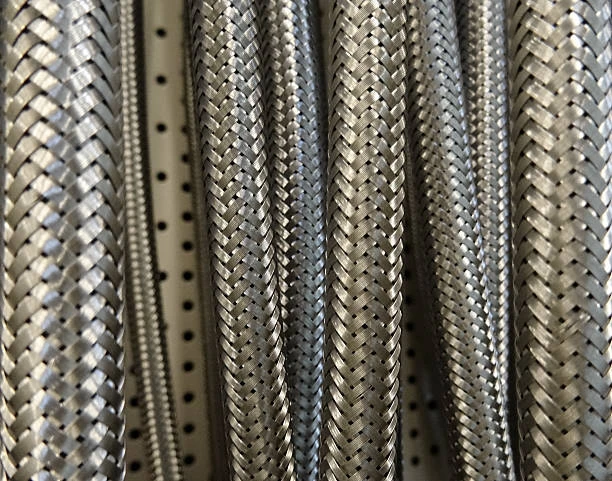

Reinforced braid hoses are flexible conduits. They transport fluids, gases, or sometimes solids within a system. Their design is far more complex than a basic pipe. These hoses typically feature a three-layer construction for maximum durability.

The inner tube is the first layer. It is compatible with the specific media flowing through it. This tube is often made of materials like synthetic rubber, PTFE, or thermoplastics. It resists degradation from the fluid itself.

A reinforcement layer surrounds the inner tube. This layer is the true heart of the hose. It consists of a strong braided or spiral-wound material. Manufacturers use high-tensile steel wire, textile yarn, or aramid fibers like Kevlar for this braid. This layer provides immense strength and contains the internal pressure.

A durable outer cover protects these internal layers. It guards against abrasion, weather, ozone, and chemicals. This cover ensures the reinforcement braid remains intact and functional.

These hoses offer several key advantages. Their design ensures reliability in the most demanding environments.

Frequently Asked Questions (FAQ)

1. Why is the reinforcement braid so important?

The braid is the primary load-bearing component. It absorbs the internal pressure of the system. Without this reinforcement, the hose would expand like a balloon and eventually burst. The braid provides the mechanical strength needed to contain high pressures safely.

2. How do I choose the right hose for my application?

You must consider several key factors. First, identify the type of fluid or gas the hose will carry. Next, know the maximum system pressure and temperature ranges. Also, consider the environmental conditions, like exposure to sunlight or chemicals. Always consult the manufacturer’s specifications to ensure a perfect match.

3. What is the difference between braided and spiral reinforcement?

Braided reinforcement typically involves two layers of wire crisscrossing in a mesh pattern. It offers excellent flexibility and is common for medium-to-high pressure applications. Spiral reinforcement involves four or six layers of wire wound in a tight helix. It provides superior strength for very high-pressure and high impulse applications, like hydraulic systems.

4. How often should I replace a reinforced braid hose?

Replacement intervals depend on the application and operating conditions. You should regularly inspect hoses for signs of wear. Look for cracks in the cover, abrasion, oil swelling, or leaks at fittings. Most manufacturers also recommend a replacement schedule based on service hours. Never ignore a hose that looks damaged.

5. Can a reinforced hose fail even if it looks fine?

Yes, internal damage can be invisible. The inner tube can degrade from chemical erosion without any external signs. The reinforcement wires can also fatigue from constant flexing and pressure cycles. Following a preventive maintenance schedule is crucial. This practice helps you replace hoses before they fail unexpectedly.

Common Uses and Application Industries

The use of reinforced braid hoses is absolutely vital across countless industries. They are the lifelines of mobile hydraulic equipment. Construction machinery like excavators and bulldozers rely on them for powerful movements. These hoses withstand high pressure and constant movement on rough job sites.

The automotive and transportation sector depends on them. They are used in power steering, brake lines, and turbocharger systems. Under the hood, they handle hot oil, fuel, and coolant. Their reliability is directly linked to vehicle safety and performance.

Industrial manufacturing plants use these hoses extensively. They supply hydraulic power to presses, robots, and injection molding machines. They also carry compressed air, water, and lubricants to various tools and stations. A single hose failure can halt an entire production line.

The agricultural industry is another major user. Tractors, combines, and other farm equipment use robust hoses for hydraulics. They also transfer water, fertilizers, and fuels. Their durability is essential for operating in dusty and demanding outdoor conditions.

Even the aerospace sector utilizes specialized reinforced hoses. They handle fuel, hydraulics, and air conditioning within aircraft. These hoses meet incredibly strict safety and performance standards. Their failure is simply not an option at 30,000 feet.

Conclusion

In summary, reinforced braid hoses are fundamental components that ensure safety and functionality. They are far more than simple connectors; they are highly engineered systems. Their layered construction provides the strength to contain immense pressures and the flexibility to operate in dynamic environments.

Choosing the correct hose requires careful attention to application details. Understanding their characteristics helps prevent costly downtime and dangerous failures. From construction sites to factory floors and vehicles on the road, these hoses perform critical duties. Always prioritize quality and proper specification. Investing in the right reinforced braid hose protects your equipment, your productivity, and most importantly, your people.

IFNS’s international standards

IFNS products comply with a wide range of international standards, including ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, GB/T 18993 series, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications ensure that our pipes and fittings meet global quality, safety, and performance requirements.

Connect

IFNS, a Chinese manufacturer with 30 years of experience, specializes in high-quality plastic pipes, fittings, and valves. Interested in IFNS’s copper fittings, copper valves, plastic pipes, or fittings? Contact us today. IFNS offers a wide range of standard pipes tailored to your needs. Explore our affordable, cost-effective valve and piping system products.

We respond to emails or faxes within 24 hours. For immediate assistance, call us anytime with questions about our products.