Introduction

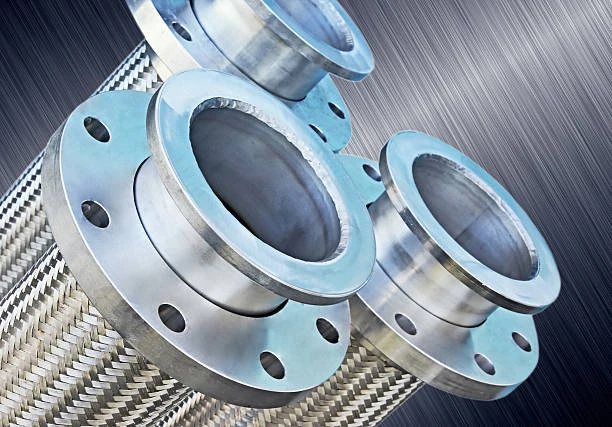

Reinforced braid hoses stand out in fluid transfer systems primarily because of their exceptional flexibility combined with remarkable strength. These specialized hoses feature a unique construction that allows them to bend and twist without compromising their structural integrity or performance. Across industries from automotive to industrial manufacturing, the flexibility of reinforced braid hoses makes them the preferred choice for applications requiring both durability and adaptability. This comprehensive guide explores what makes these hoses so flexible, their key characteristics, diverse applications, and answers to common questions about their use and maintenance.

What Makes Reinforced Braid Hoses Flexible?

The flexibility of reinforced braid hoses comes from their innovative multi-layer design:

- Inner Tube: Typically made from flexible materials like synthetic rubber, thermoplastic, or PTFE that provide the initial bendability

- Reinforcement Layer: The braided metal (usually stainless steel) or synthetic fibers are woven in a way that allows movement while maintaining strength

- Outer Cover: Protective jacket that moves with the hose without cracking or splitting

The braiding pattern is particularly crucial – the crisscross weave creates a structure that can expand and contract with pressure changes while maintaining its shape. This gives the hose its unique combination of properties:

- Can bend to tight radii without kinking

- Maintains flow efficiency even when twisted or coiled

- Absorbs vibration better than rigid piping

- Easier to install in confined spaces

- More resistant to fatigue from repeated bending

Key Flexibility Characteristics

Several factors determine how flexible a particular reinforced braid hose will be:

- Material Composition: Stainless steel braids offer more flexibility than carbon steel, while synthetic braids (like aramid) provide the most bendability

- Braid Density: More braids per inch increases strength but reduces flexibility, while fewer braids does the opposite

- Inner Tube Material: Thermoplastic tubes typically allow more bending than rubber ones

- Diameter: Smaller diameter hoses naturally bend more easily than larger ones

- Temperature Range: Flexibility decreases in extremely cold environments

Manufacturers often rate hoses by their minimum bend radius – the tightest curve they can make without damage. This is usually 4-6 times the hose diameter for most reinforced braid models.

Common Applications Leveraging Flexibility

The flexible nature of reinforced braid hoses makes them ideal for:

Automotive and Transportation

- Fuel Lines: Need to bend around engine components

- Coolant Systems: Require routing through tight spaces

- Brake Lines: Must flex with suspension movement

Industrial Machinery

- Robotic Arms: Need hoses that move continuously

- CNC Equipment: Require flexible coolant delivery

- Assembly Lines: Benefit from adaptable connections

Hydraulic Systems

- Construction Equipment: Excavators and loaders need hoses that bend with moving parts

- Agricultural Machinery: Must flex with implement movement

Aerospace and Defense

- Fuel Transfer: Aircraft need lightweight, flexible hoses

- Hydraulic Controls: Require precise movement capability

Medical Equipment

- Gas Delivery: Needs clean, kink-resistant lines

- Fluid Transfer: Requires reliable flexible connections

Frequently Asked Questions (FAQ)

1. How flexible are reinforced braid hoses compared to other types?

They offer significantly better flexibility than rigid metal piping while maintaining more strength than unreinforced rubber hoses. The braided construction provides the perfect balance.

2. Can the flexibility decrease over time?

Yes, with prolonged use, especially in high-temperature environments, hoses can become less flexible. Regular inspection helps identify when replacement is needed.

3. What’s the best way to maximize hose flexibility during installation?

Always follow the manufacturer’s recommended bend radius and avoid sharp angles. Use proper supports and allow some slack for movement.

4. Does flexibility affect pressure rating?

To some degree – more flexible hoses often have slightly lower maximum pressure ratings than stiffer counterparts of similar size. Always check specifications.

5. Can I increase a hose’s flexibility by using a longer length?

While this can help in some situations, it’s better to select a hose designed with the appropriate flexibility characteristics for your application.

Maintaining Optimal Flexibility

To keep reinforced braid hoses performing at their flexible best:

- Store properly coiled, not tightly bent

- Protect from extreme temperatures when possible

- Clean regularly to prevent buildup that could stiffen the hose

- Inspect for any braid damage that could affect movement

- Replace at first signs of cracking or reduced flexibility

Conclusion

The flexibility of reinforced braid hoses represents a perfect marriage of engineering and practicality. By combining durable materials with intelligent braiding techniques, these hoses deliver unmatched versatility in fluid and gas transfer applications. Their ability to bend, twist, and move without sacrificing strength or reliability makes them indispensable across countless industries. When selecting a reinforced braid hose, carefully consider the flexibility requirements of your specific application – the right balance of bendability and durability will ensure optimal performance and longevity. With proper selection, installation, and maintenance, these hoses will provide reliable, flexible service for years to come.

IFNS’s international standards

IFNS products comply with a wide range of international standards, including ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, GB/T 18993 series, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications ensure that our pipes and fittings meet global quality, safety, and performance requirements.

Connect

IFNS, a Chinese manufacturer with 30 years of experience, specializes in high-quality plastic pipes, fittings, and valves. Interested in IFNS’s copper fittings, copper valves, plastic pipes, or fittings? Contact us today. IFNS offers a wide range of standard pipes tailored to your needs. Explore our affordable, cost-effective valve and piping system products.

We respond to emails or faxes within 24 hours. For immediate assistance, call us anytime with questions about our products.